Cheap Energy:Improvement 1 - Ever wonder how certain buildings keep a cozy environment inside while its scorching hot outside or freezing cold? I am very curious about this question! Because they also involve the heat recovery coil. In this guide, we'll discuss what these coils do, and why they work so well.

There is a critical requirement for heat recovery coils across HVAC systems. Heating, ventilation and air conditioning is what they say HVAC stands for. These systems are designed to regulate the indoor heat and make buildings operational, ensuring that there is also airflow inside along with segmented air conditioning. Heat recovery coils are designed to recover some of the heat that would otherwise escape up-the-warm-air-flue when it vents out. That way, instead of wasting those BTUs it can heat up the fresh air entering from outside. It is the ability of a building to function at minimum energy consumption and provide thermal comfort inside it.

It also provides energy conservation to the buildings by utilising heat recovery coils, making it a cost effective solution too. In the Winter, fresh outside air must be warmed to a nice comfortable temperature inside before it can be put into people's homes. There is other heat source like conventional ways of electricity or gas/oil and that can be expensive. Heat recovery coils do provide some partial energy savings by collecting a little of the latent warmth that already exists in a building and using it over. In truth, because If power payments fall as a result of they want fewer energy to heat the air andAs a whole buildings are paying less. Isn't that what everyone wants to hear?

Save you money in your heating bill; Improve comfort for the users (Building occupants can use comfortably); We require air to be healthy and well, however because it is necessary we have cold or hot just take examples of products being natural keeping everyone at room temperature person. A building can take fresh air in through heat recovery coils, meaning that less energy is needed to then warm or cool the space. This will all help people experience a more comfortable, cleaner and an overall better indoor environment.

This has led to the greater use of heat recovery coils, because they offer a high level of efficiency. That is efficient, it uses little of the energy when working. Heat recovery coils in HVAC is always beneficial on code energy and are most good to save the required eergy waste. In the meantime we sit around and mourn the lack of a new gadget that helps reduce greenhouse gasses, as something which is in everyone's interest.

In other words, sustainable architecture is simply not making NON-sustainable buildings! These industrious heat recovery coils are central to any sustainable building design, ensures that valuable energy is not wasted. HR-heat recovery coils in HVAC systems reduce the energy needed to heat or cool fresh air entering buildings, thus increasing their sustainability. This makes them more eco friendly and this way we all can also do our bit for the planet.

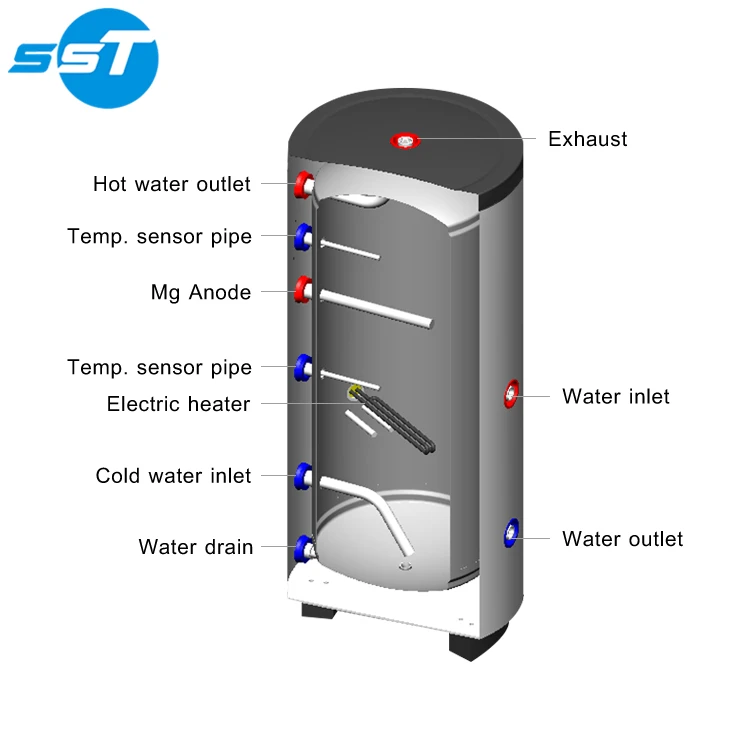

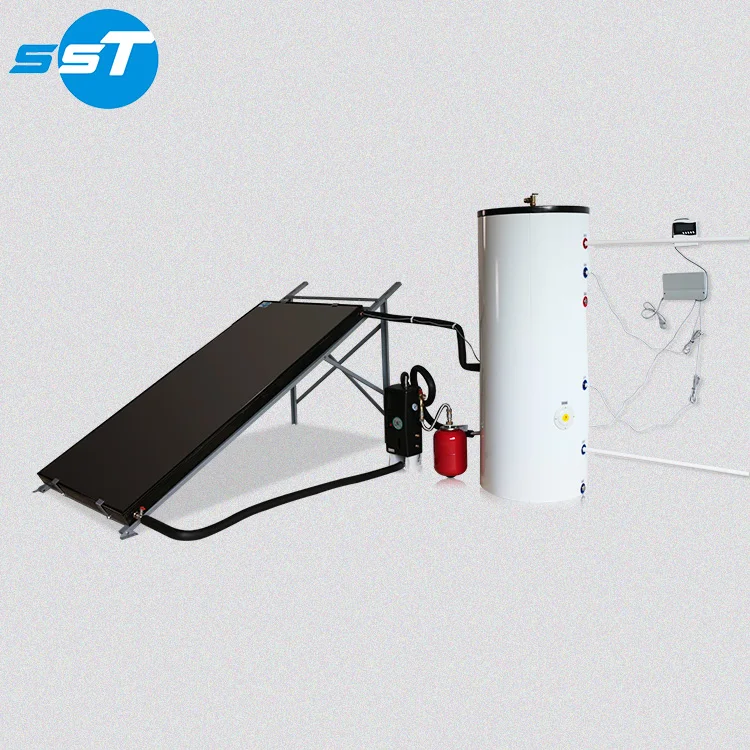

Products include: heat recovery coil heat recovery tanks, storage tanks hot water tanks, gas boilers and heat pump water tanks. SST also has a variety of stainless steel items, including water cylinders, storage water and solar systems. SST offer ODM and OEM service 20 Technology and RD engineer, 6 automatic production lines that ensure welding quality and efficiency.

SST is certified with CE CB, ERP, and CE certifications for the European market. Watermark is designed for the Australian market, UL is for North America, KTW and WRAS are intended for UK drinking standard. Our heat recovery coil has the ability to attain a heating loss of A+. Also, ISO9001, ISO14001, ISO45001 and all other materials are certified ROHS.

SST Heating Energy Co., Ltd is established in 2006 and is the largest manufacturer and exporter of stainless steel customized water tank. It is also the most experienced manufacturer of DUPLEX heat recovery coil with the leading technology of China. Obtains more than 50 inventions and utility patents for model designs. Over 18 years SST has exported water tanks and is the No. 1 exporter of water tanks. The area of the factory is more than 30000m2, and monthly production of 10, 000 pcs. Heating loss reaches A+.

SST have stainless steel material lab for heat recovery coil, the lab includes: raw material component analyze and spectrograph test, it can ensure that our raw materials meet the ROHS and standards. Point corrosion test to test different stainless steel materials' corrosion resistance; Metallographic test to determine the changes in the chemical composition of raw materials and materials following welding. Tensile test, to test the strength, fatigue, and hardness. Also we have tests for fatigue and pressure for each tank, to ensure that the tank is certified.