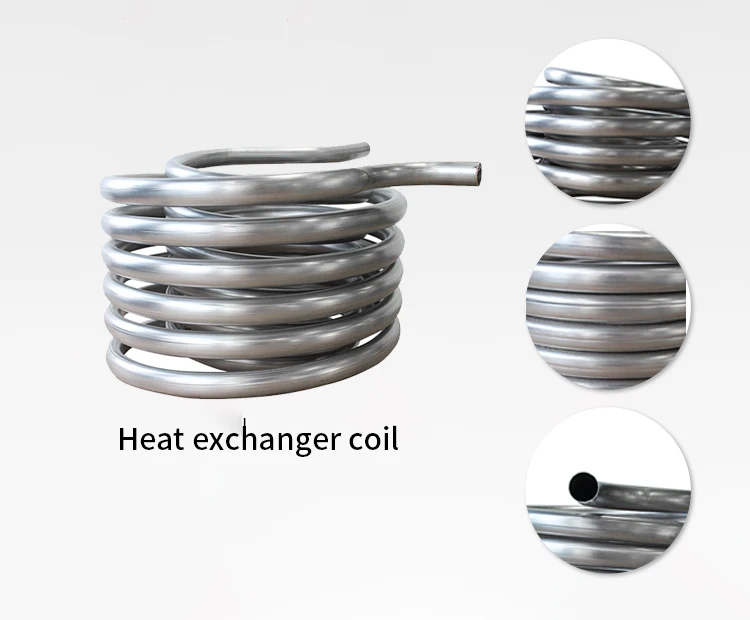

A hőcserélők egyedi eszközök, amelyek hőt továbbítanak az egyik helyről a másikra. Képzelj el, mint egy hősét keresztülteszt! Például egy rostalanacélis spirális hőcserélő erős spirálokkal éri el ezt. Ezek olyan hőcserélők, amelyek bizonyítottan megbízhatóak és független kezdeményezők a hazai melegesség terén.

A rostalanacél nagyon tartós anyag, amely képes magas hőmérsékletű és nyomásos helyzetekben is fenntartani tulajdonságait. Ez azt jelenti, hogy egy rostalanacélis spirális hőcserélő, nem olyan, mint egy réz vagy alumíniumból készült (ami gyakoribb), sok évig működhet anélkül, hogy szükséges lenne javítani vagy cserélni. Egyszerűen fogalmazva: van egy barátod, aki segít!

Ha a fűtési rendszered szegénységes teljesítményű vagy nem elegendő a hőellátás, érdemes lehet megfontolni a rostalanacélis spirális hőcserélő használatát. Ez nem használ elektromos energiat, és csökkentheti a fűtőberendezés költségeidet, ugyanakkor biztosítja a jól működő eszköz által nyújtott meleglést. Képzelj el, hogy meleg és kényelmes vagy a házadban anélkül, hogy túl sok energiát fogyasztanál!

Mi az a rostalanacélis spirális hőcserélő és hogyan működik? Az áramokat hő között tereli át a folyadékok között. Például egy fűtési rendszerben a hő a forróság a házban keringő forró vízből és a ráfúvott hideg levegóból ered, amelyen fut át ezeken az nyitott végű kimeneteken alkalmazott pontokon […] A hőt tovább adja egy másiknak, mintha saját melegedet osztanád meg.

Rèzületlen acél spirálos hőcserélő helyettesítésre a rézsesére! Ez a típusú acél jól ellenáll a rézszel, és ezért a hőcserélő hatékonyabban és hosszabb ideig működhet, mint más fémmel. Jobban terjeszti el a fűtést. Nyugodtan ülhet vissza otthona, a fűtés bekapcsolva, és ne aggódjon annyira, hogy a réz mindent megsemmisíteni fog.

Ezek a hőcserélők arra szolgálnak, hogy átvihessék a gyújtóanyag égésből származó hőt egy folyadékos vízre, amely áramlik a bojlerrendszerén keresztül. Segítségükkel átkerül a hő a gyújtóból az udvarba levegővel. És egy hőpumpában átvikszik a hőt a kinti levegőből, és belső részre továbbítja, ahol azt szeretné.

Ilyen kemény környezetben a rèzületlen acél csöveknek többek között vastagabbaknak és erősebbnek kell lenniük, mint általánosan. Olyan, mintha supererőket kapnának! Azonban akár a legnehezebb feltételek között is ezek a hőcserélők képesek tökéletesen működni.

Az SST rendelkezik rozsdamentes acél alapanyagok vizsgálatára szolgáló anyagvizsgáló laboratóriummal, amely az alapanyagok összetétel-analízisét és spektrográfiai vizsgálatát végzi; ezáltal ellenőrizhető, hogy az általunk használt alapanyagok megfelelnek-e az ROHS előírásoknak és egyéb szabványoknak. A pontszerű korróziós vizsgálat célja a különböző rozsdamentes acél anyagok korrózióállóságának vizsgálata; a rozsdamentes acél csavart hőcserélőnél a hegesztést követően ellenőrizzük az alapanyagok és egyéb anyagok kémiai összetételének változását. Húzóvizsgálat a szilárdság, a rugalmasság és a fáradási ellenállás meghatározására. Emellett minden tartályra feszültségvizsgálatot és fáradásvizsgálatot is végzünk annak biztosítására, hogy termékeink mindegyike tanúsított legyen.

Az SST rozsdamentes acél tekercs hőcserélő Kft. 2006-ban alakult, és Kína legnagyobb gyártója és exportőre egyedi rozsdamentes acél víztartályoknak, valamint a kínai piacon a legrégebbi, vezető technológiával rendelkező DUPLEX rozsdamentes acél víztartály-gyártó. Több mint 50 szabadalmat jegyeztek be tervek és használati minták tekintetében. Az SST több mint 18 éve exportál víztartályokat, és az országban első helyen áll az exportált víztartályok mennyiségét tekintve; saját gyárának területe meghaladja a 30 000 m²-t, havi termelése több mint 10 000 darab, a hőveszteség osztálya A+.

A tanúsításokat illetően az SST rendelkezik CE-, rozsdamentes acél tekercs hőcserélő-, ERP- és PED-tanúsítvánnyal az európai piac szolgálata érdekében. A Watermark tanúsítás az ausztrál, az UL tanúsítás Észak-Amerika piacára vonatkozik, a KTW és a WRAS pedig az Egyesült Királyság ivóvíz-szabványaira. Víztartályaink jelenleg elérhetik a hőveszteség A+ osztályát. Emellett az ISO9001, az ISO14001, az ISO45001 és minden egyéb anyag ROHS-tanúsítással rendelkezik.

Az SST termékei közé tartozik az állítható acél tekercsos hőcserélő víztartály, a gázkazán tartálya, a puffer tartály, az elektromos víztartály, a nyomás alatti napenergiás víztartály, a melegvíz-tartály, a tároló víztartály, valamint a hővisszanyeréses víztartályok, napenergiás rendszer kiegészítők és kapcsolódó egyedi állítható acél termékek. Az SST ODM- és OEM-megoldásokat kínál, 20 technológiai és kutatás-fejlesztési szakértőt foglalkoztat, valamint 6 automatizált gyártósorral rendelkezik, amelyek biztosítják a legmagasabb minőségű hegesztést.