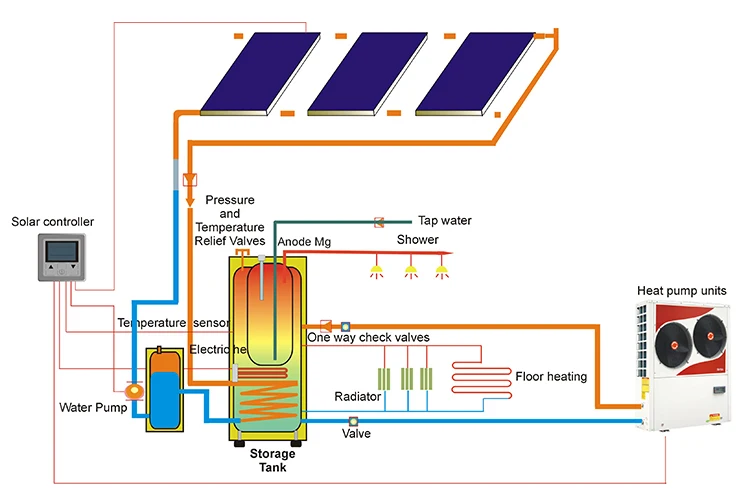

What is a boiler calorifier? The function of a tank system is to warm water up through the wish for boiler and storing that heated h2o in a holds until it be necessitated. What happens when you turn on your heater to heat up the place is that hot water runs through pipes throughout out the house and it basically makes everything warm for you (and or family).

This water goes into a storage tank which acts as an insulated vessel that maintains the temperature of your hot water until you turn on the tap. Sort of like a huge thermos keeping your drink warm all day long! When you turn on your heater, a small pump will circulate that water out of the storage tank and through these pipes throughout your house. This means that you will always have heat when needed, to keep your home comfortable.

The main advantage of installing a Boiler Calorifier is that it promotes the following: A better, more efficient heating system. This way, less fuel is burnt to heat your home and prevent the boiler from using energy repeatedly. This means your heating bills can be reduced, which is great soothing words to your wallet! In the winter and you want your home to be heated, saving money is always welcome.

One of the other bonuses to utilising a boiler calorifier is that it can provide you with an endless supply of hot water 24/7, no matter how chilly it may be outside. Becuase the hot water is in tank, you always have a bank of heat available center ready when ever needed. That way you never have to wait for your boiler or the radiators all over your home to heat up finally so that…violà! You will feel warmth in a jiffy, something that guarantees you do not leave your house to enjoy the heat of winter.

The size of the storage tank is an important thing to think about when you are choosing a boiler calorifier. The larger your home is, the more square footage you have to heat and cool – so this means a bigger storage tank. A bigger tank lets you hold more hot water, which is nice feature for keeping your home warm. You may also want to find a model with high efficiency. This rating lets you know how efficient the machine is on using energy, in order to help keep your heating costs lower.

Flow-piping Leaks: If you have any leaks in the pipes that run from boiler calorifier and your heater, then this can be wastage of energy along with a toll on efficiency. Special attention should be paid to any possible leaks in the pipes, and they must be solved quickly. And it also pays to repair leaks as and when they are found- Not only is water an expensive resource, but so too hoovering up those drips can be energy intensive.

Regularly maintain your boiler calorifier: Regular servicing by a professional can help to ensure that issues are caught before they occur. Make an appointment for annual maintenance This is another excellent method to prevent things from getting out of hand in the first place, we can work together as a team and debugging will be done earlier than later.

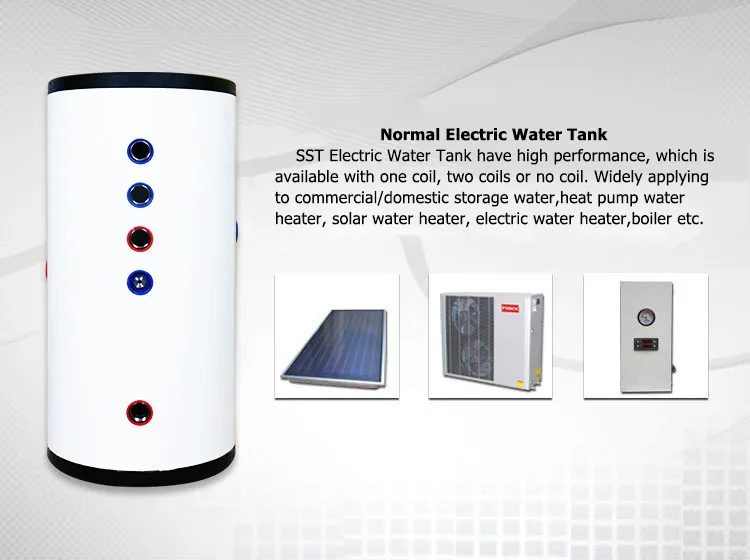

SST is boiler calorifier with CE CB, ERP, and CE certificates for European markets. Watermark is for the Australian market, UL is for North America, and KTW and WRAS are designed for UK drinking standard. Our water tank now can reach a temperature loss of A+. Additionally, ISO9001, ISO14001, ISO45001 and all materials meet ROHS.

SST Heating boiler calorifier Co., Ltd was established in the year the year 2006. It is the largest producer of DUPLEX stainless water tanks using the latest technology. It has more than 50 inventions and utility patents for model designs. Over 18 years SST has been exporting water tanks, and is the No. 1 exporter of water tanks. The factory area is greater than 30000m2, and monthly production of 10, 000 pieces. Heating loss can reach A+.

The range of products includes solar system accessories including heat recovery tanks storage tanks, hot water tanks, gas boilers, as well as heat pump water tanks. SST also offers an array of stainless steel products, such as boiler calorifier, water cylinders and solar systems. SST offers OEM and ODM service 20 Technology, RD engineer, six automated production lines to guarantee the quality of welding and effectiveness.

SST have stainless steel material laboratory for raw material, the laboratory will perform raw material component analyze and spectrograph test, which will ensure that the raw materials we use conform to the ROHS standards; Point corrosion test to evaluate different stainless steel materials' corrosion resistance; Metallographic test, to determine the changes in the tissue composition of raw materials and the materials following welding. Tensile test, to determine the strength, resistance to fatigue and hardness. Also we have stress test and boiler calorifier for each tank, to make sure that all materials are certified.