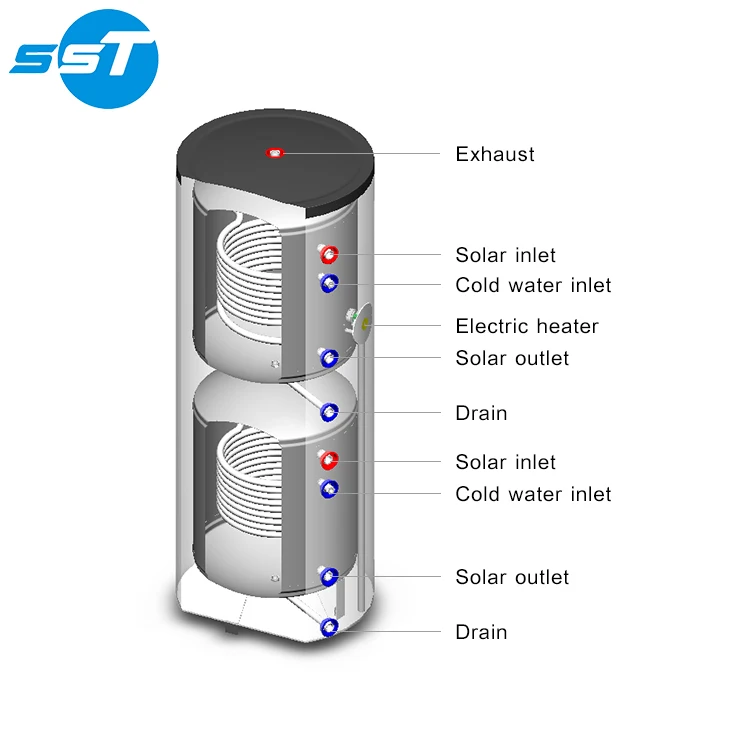

Systèmes de chaudière et de réservoir d'eau, car ceux-ci utilisent l'énergie générée pour chauffer leurs propres sources d'eau chaude ou tiède pour votre propriété. Ces techniques vous permettent d'allumer une chaudière afin de chauffer l'eau qui est stockée dans un réservoir spécifique et de grande taille. Des tuyaux connectent le réservoir d'eau au feu, et la chaleur de celui-ci passe dans une poche spéciale contenant un liquide en ébullition. Lorsque l'eau dans cet objet est suffisamment chauffée, elle est acheminée vers des tuyaux où elle parvient aux éviers et autres appareils tels que les douches, les lave-vaisselle ou les machines à laver. C'est un processus qui vous permettra d'obtenir de l'eau chaude à chaque fois sans aucun problème.

Les systèmes de chauffe-eau à réservoir ont leurs avantages et inconvénients — vous devez savoir ce que nous entendons par là. Du côté positif, il s'agit de systèmes spécialement conçus pour livrer rapidement de l'eau chaude selon les besoins. Cela signifie presque aucun temps d'attente avant votre prochaine douche chaude ou votre vaisselle sale. Ils coûtent également généralement moins cher que la plupart des autres types de chauffe-eau, ce qui vous permet de faire des économies. Ou alors, au contraire, nous avons aussi beaucoup d'inconvénients à prendre en compte. Si vous disposez d'un espace réduit, les systèmes de chauffe-eau à réservoir peuvent représenter un volume intenable dans votre maison ou votre entreprise. De plus, ces systèmes ont tendance à manquer d'eau chaude après une longue période d'utilisation. Dans ce cas, il est probable que vous devrez attendre un certain temps avant que l'eau ne se réchauffe à nouveau et puisse être utilisée.

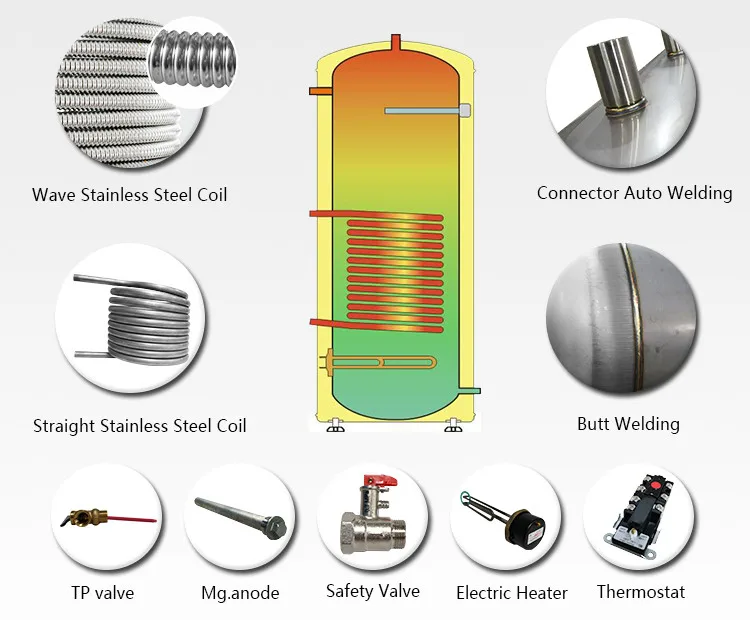

Cependant, pour vous assurer que votre système de chauffe-eau à réservoir fonctionne correctement et efficacement, il faut effectuer quelques opérations de maintenance. La chose importante est que vous devez d'abord vérifier la température de l'eau dans votre réservoir. Si la température est trop basse, vous devez l'augmenter en réglant votre thermostat. Cela aide à vous assurer que vous avez toujours de l'eau chaude lorsque nécessaire. Ensuite, il faut examiner la soupape de pression. Cette soupape est très essentielle, donc le système doit être révisé pour s'assurer qu'elle fonctionne. Une autre bonne idée est de vider le réservoir au moins une fois tous les quelques mois. Cela permet d'éliminer un peu de saleté ou de dépôt filtré du système, rendant votre unité de chauffage plus propre.

Il y a plusieurs choses à prendre en compte si vous souhaitez faire installer un système de réservoir d'eau chez vous. Oubliez le réservoir un instant> Tout d'abord, envisagez l'emplacement de votre aquarium de récif. Il doit être placé là où la pluie ne tombe pas et où il n'y a aucune autre sorte de menace. Vous devez également prendre en compte la taille du réservoir. Si vous avez une grande famille ou menez de nombreuses activités, cela implique que vous pourriez avoir besoin de quelque chose de légèrement plus grand si tout le monde dans le foyer utilise de l'eau chaude. Dernière étape - Réfléchissez au prix de ce système. L'installation d'un chauffe-eau de réservoir peut être assez coûteuse, assurez-vous donc d'être en mesure de le faire avant de continuer.

Si vous cherchez à installer un système de chauffe-eau à réservoir chez vous ou dans votre entreprise, il y a de bonnes raisons ainsi que des éléments à prendre en compte. Étape Un : Évaluer la taille de votre maison ou de votre entreprise. Si vous avez une famille plus nombreuse ou une entreprise de taille importante, vous aurez besoin d'un réservoir plus grand pour satisfaire tout le monde avec la quantité d'eau chaude disponible. Coût : Il faut également considérer le prix. Installer des systèmes de chauffe-eau à réservoir est coûteux, assurez-vous donc d'aligner votre budget et d'être capable de le rembourser. Enfin, choisissez le type de carburant pour votre système sans conduit. Gaz ou électrique autreFAcaret système : Vous devez choisir ce qui correspond bien à votre situation particulière et à vos besoins.

SST Heating Energy Co., Ltd a été fondée en 2006 ; c'est le fabricant et exportateur le plus important de cuves à eau sur mesure en acier inoxydable, ainsi que le fabricant le plus expérimenté de cuves à eau en acier inoxydable duplex, doté de la technologie la plus avancée en Chine. L'entreprise détient plus de 50 brevets d'invention et de brevets d'utilité portant sur des modèles. Depuis sa création, SST exporte des cuves à eau et se classe au premier rang des exportateurs de cuves à eau. La superficie de l'usine est supérieure à 30 000 m², et la production mensuelle concerne des systèmes de chaudière et de cuve à eau. Les pertes thermiques sont aussi faibles que la classe A+.

SST dispose d’un laboratoire de matériaux en acier inoxydable dédié aux systèmes de chaudières et de réservoirs d’eau ; ce laboratoire comprend : l’analyse des composants des matières premières et des essais spectrographiques, ce qui permet de garantir que nos matières premières respectent les normes ROHS et autres exigences réglementaires. Un essai de corrosion localisée permet d’évaluer la résistance à la corrosion de différents aciers inoxydables ; un essai métallographique permet de déterminer les modifications de la composition chimique des matières premières et des matériaux après soudage. Un essai de traction évalue la résistance mécanique, la résistance à la fatigue et la dureté. En outre, chaque réservoir fait l’objet d’essais de fatigue et de pression afin de garantir sa certification.

Les systèmes de chaudières et de réservoirs d’eau SST sont certifiés CE, CB, ERP et CE pour les marchés européens. La marque Watermark est destinée au marché australien, la certification UL concerne l’Amérique du Nord, tandis que les certifications KTW et WRAS répondent aux normes britanniques relatives à l’eau potable. Nos réservoirs d’eau atteignent désormais une classe de perte thermique A+. Par ailleurs, SST est certifiée ISO 9001, ISO 14001 et ISO 45001, et tous ses matériaux sont conformes à la directive ROHS.

Les produits comprennent : des systèmes de chaudières avec réservoir d’eau, des réservoirs de récupération de chaleur, des réservoirs de stockage, des réservoirs d’eau chaude, des chaudières à gaz et des réservoirs d’eau pour pompes à chaleur. SST propose également une variété d’articles en acier inoxydable, notamment des ballons d’eau chaude, des systèmes de stockage d’eau et des systèmes solaires. SST offre des services ODM et OEM, dispose de 20 ingénieurs spécialisés dans la technologie et la recherche-développement, ainsi que de 6 lignes de production automatisées garantissant la qualité et l’efficacité du soudage.