Énergie bon marché : Amélioration 1 - Vous vous êtes déjà demandé comment certains bâtiments maintiennent un environnement agréable à l'intérieur alors qu'il fait une chaleur accablante à l'extérieur ou qu'il gèle ? Je suis très curieux à propos de cette question ! Parce qu'ils impliquent également la bobine de récupération de chaleur. Dans ce guide, nous discuterons de ce que ces bobines font et pourquoi elles fonctionnent si bien.

Il existe un besoin critique de récupérateurs de chaleur dans les systèmes HVAC. On dit que HVAC signifie chauffage, ventilation et climatisation. Ces systèmes sont conçus pour réguler la chaleur intérieure et rendre les bâtiments opérationnels, en veillant à ce qu'il y ait également un flux d'air à l'intérieur ainsi qu'une climatisation segmentée. Les récupérateurs de chaleur sont conçus pour récupérer une partie de la chaleur qui s'échapperait sinon par le conduit d'évacuation des airs chauds lorsqu'il se vide. Ainsi, au lieu de gaspiller ces BTU, ils peuvent chauffer l'air frais entrant de l'extérieur. C'est la capacité d'un bâtiment à fonctionner avec une consommation minimale d'énergie tout en offrant un confort thermique à l'intérieur.

Il offre également une économie d'énergie aux bâtiments en utilisant des bobines de récupération de chaleur, ce qui en fait également une solution économique. En hiver, l'air frais extérieur doit être réchauffé à une température agréable à l'intérieur avant d'être introduit dans les maisons. Il existe d'autres sources de chaleur comme les méthodes conventionnelles d'électricité ou de gaz/pétrole et cela peut être coûteux. Les bobines de récupération de chaleur offrent certaines économies d'énergie partielles en collectant un peu de la chaleur latente qui existe déjà dans un bâtiment et en l'utilisant. En réalité, parce que si les paiements d'énergie diminuent en raison du fait qu'ils ont besoin de moins d'énergie pour chauffer l'air et, dans l'ensemble, les bâtiments paient moins. N'est-ce pas ce que tout le monde aimerait entendre ?

Économisez de l'argent sur votre facture de chauffage ; Améliorez le confort des utilisateurs (les occupants du bâtiment peuvent utiliser confortablement) ; Nous avons besoin d'air sain et propre, cependant, puisqu'il est nécessaire, nous avons froid ou chaud, prenons simplement des exemples de produits naturels qui maintiennent tout le monde à une température ambiante. Un bâtiment peut faire entrer de l'air frais grâce à des bobines de récupération de chaleur, ce qui signifie qu'il faut moins d'énergie pour ensuite chauffer ou refroidir l'espace. Cela contribuera à offrir aux gens un environnement intérieur plus confortable, plus propre et globalement meilleur.

Cela a conduit à une utilisation accrue des bobines de récupération de chaleur, car elles offrent un haut niveau d'efficacité. C'est efficace, cela utilise peu d'énergie lorsqu'il fonctionne. Les bobines de récupération de chaleur dans les systèmes HVAC sont toujours bénéfiques en termes d'énergie conforme au code et sont excellentes pour économiser l'énergie gaspillée requise. Pendant ce temps, nous restons assis à regretter l'absence d'un nouveau gadget qui aide à réduire les gaz à effet de serre, ce qui est dans l'intérêt de tous.

Autrement dit, l'architecture durable, ce n'est simplement pas construire des bâtiments NON-durables ! Ces bobines de récupération de chaleur industrielles sont centrales dans toute conception de bâtiment durable, en veillant à ce que l'énergie précieuse ne soit pas gaspillée. Les bobines de récupération de chaleur (HR) dans les systèmes HVAC réduisent l'énergie nécessaire pour chauffer ou refroidir l'air frais entrant dans les bâtiments, augmentant ainsi leur durabilité. Cela les rend plus respectueux de l'environnement et ainsi, nous pouvons tous faire notre part pour la planète.

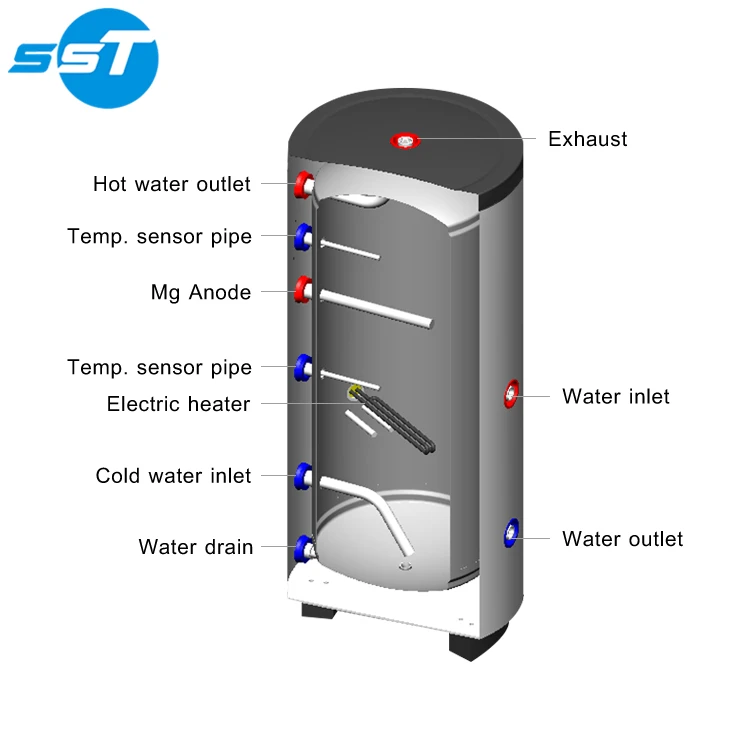

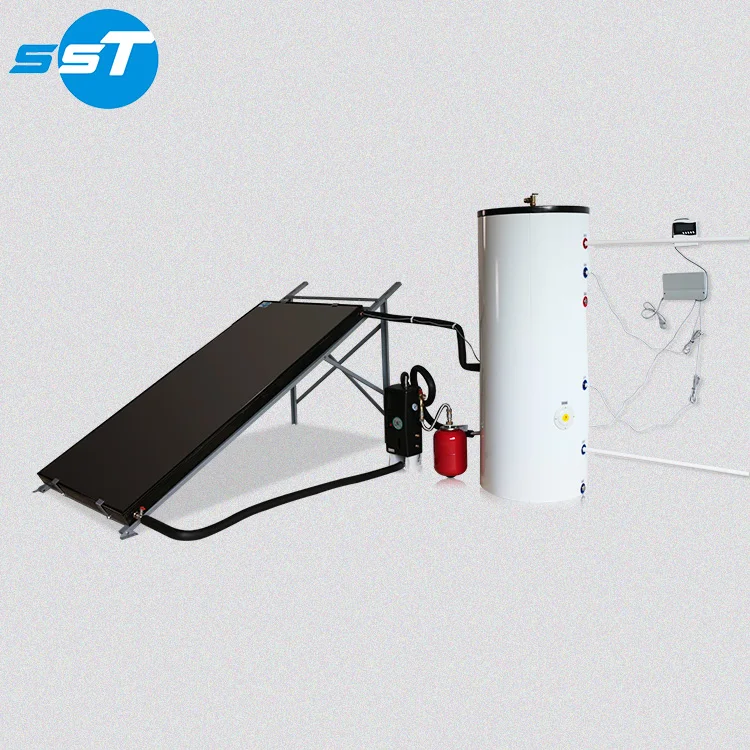

Les produits comprennent : serpentins de récupération de chaleur, réservoirs de récupération de chaleur, réservoirs de stockage, réservoirs d’eau chaude, chaudières à gaz et réservoirs pour pompes à chaleur. SST propose également une grande variété d’articles en acier inoxydable, notamment des chauffe-eaux, des réservoirs d’eau chaude et des systèmes solaires. SST offre des services ODM et OEM, avec 20 ingénieurs spécialisés en technologie et en R&D, ainsi que 6 lignes de production automatisées garantissant la qualité et l’efficacité des soudures.

SST est certifiée selon les normes CE, CB, ERP et CE pour le marché européen. La marque Watermark est destinée au marché australien, la certification UL concerne l’Amérique du Nord, tandis que les certifications KTW et WRAS répondent aux normes britanniques relatives à l’eau potable. Notre serpentin de récupération de chaleur permet d’atteindre une classe d’efficacité énergétique A+ en matière de pertes thermiques. Par ailleurs, SST est certifiée ISO 9001, ISO 14001 et ISO 45001, et tous ses matériaux sont conformes à la norme ROHS.

SST Heating Energy Co., Ltd a été fondée en 2006 et est le plus grand fabricant et exportateur de réservoirs d’eau sur mesure en acier inoxydable. Elle est également le fabricant le plus expérimenté de serpentins de récupération de chaleur en duplex, disposant de la technologie de pointe en Chine. Elle détient plus de 50 brevets d’invention et de brevets d’utilité pour ses modèles. Depuis plus de 18 ans, SST exporte des réservoirs d’eau et se classe au premier rang des exportateurs de réservoirs d’eau. La superficie de l’usine dépasse 30 000 m², avec une production mensuelle de 10 000 pièces. Les pertes thermiques atteignent la classe A+.

SST dispose d’un laboratoire en acier inoxydable dédié aux serpentins de récupération thermique ; ce laboratoire comprend : l’analyse des composants des matières premières et des essais spectrographiques, ce qui permet de garantir que nos matières premières répondent aux exigences de la directive RoHS et aux normes en vigueur. Un essai de corrosion localisée permet d’évaluer la résistance à la corrosion de différents aciers inoxydables ; un essai métallographique permet de déterminer les modifications de la composition chimique des matières premières et des matériaux après soudage. Un essai de traction évalue la résistance mécanique, la résistance à la fatigue et la dureté. En outre, chaque réservoir fait l’objet d’essais de fatigue et de pression afin de garantir sa certification.