Combination boiler and hot water tank for your home; so many reasons to change A Combi-Boilersystem heats the water as it is required. Yes, this is the new norm actually if you like as that means there will be no more waiting for hot water from those age-old big storage tanks. You can just slap some boiling water instead. Hot water cylinder - This is essentially a tank for storing hot that will be available the minute you need boiling waters.

The main advantage of upgrading to this system is that it saves you so much space in your home. It requires less physical space when combined to heat your hot water and provide heating than the same work which is done using a traditional tank with storage of that heated water. This can make a world of difference, particularly in smaller homes. You will also save on your energy costs by replacing the existing one, so this is a positive benefit as well. One of the sole reasons for Combi boilers being cost-effective is that they directly heat up water as compared to conventional hot boiling tanks. Energy savings over the life of bills

But How Does Boiler Work With Hot Water Cylinder In Home The vital element behind a boiler is the water that it heats up. Once the water is properly hot, it can be sent through pipes to different areas of your house (wherever you use heat or need on-demand warm running water for showers and dishes). This boiler is surrounded by a hot water cylinder, which itself in fact is actually a storage tank that holds all the hot water until you need it.

Boiling water floods in the cylinder and stays warm until it is used a few thanks to your boiler that heats and circulates your running stream of trouble. This is a cylinder that cooks and keeps it warm so you can use anytime day or night. Typically, the hot water cylinder is kept at places like in a closet or up there within your attic to be able which will give you that small additional free area inside of your living space.

Well, That is something you will need to do keeping things perfect as boilers and hot water cylinder system in working order fully which means everything should work fine. Moreover, maintenance checks will allow your system to last for the perfect period and enhance efficiency as well. Get everything up to standard - Hire an appropriate, certified heating tech to take a look at your setup once every year. This is critical because this enables them to address any possible issues so they do not turn into much larger problems.

The steam pressure of the boiler is no less important. Too little pressure applied will prevent the system from working properly. Consequently it is so alluringly convenient; to kept the water level under control and if necessary top up the pressure gauge. The other one you will like to look at is the pilot light, it gets the boiler running. Not having a bomber system in winter vs. killing germs with hot showers instead of cold ones, the difference is clear: you need your pilot light to function properly.

A common example of the issue is pipes that make loud noises and bang. And it seems to be air inside the system creating this noise. You can fix this by bleeding the air from your radiators - or calling a heating engineer to do it for you. Whenever you smell natural gas, turn off the supply of that right away and open doors/windows as fast as you can so fresh air may pass. You then have to call out a gas specialist person and get them to come in and inspect your boiler.

boiler and hot water cylinder is founded in 2006and is the largest manufacturer and exporter of custom stainless steel water tank and the oldest producer of DUPLEX stainless steel water tanks that utilizes the latest technology for in China. It has more than 50 inventions and utility model patents. SST export water tank for over 18 years, is No. 1 water tank exporter and has a factory with an area of over 30, 000 square meters, output per month of more than 10, 000pcs. Heating loss reach A+;

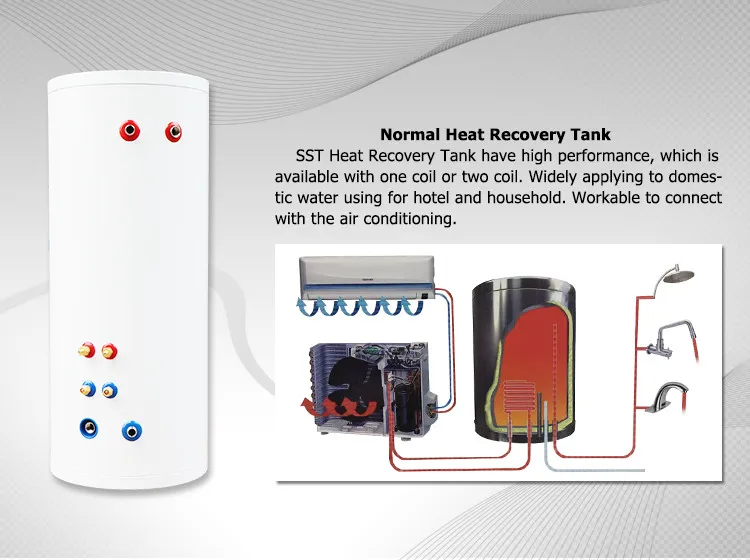

SST products cover: heat pump water tank, buffer tank made of gas, gas boiler electric water tank, pressure solar water tank hot water tank storage water tank, heat recovery water tank, solar system related accessories, and other stainless steel custom-designed products. SST has boiler and hot water cylinder and OEM services, 20 Technology and RD experts, and 6 automated production lines that ensure high-quality welding.

Concerning certification, SST had CE, boiler and hot water cylinder, ERP, and PED to serve the Europe market. Watermark is for the Australian market, UL is for North America, KTW and WRAS are for UK drinking standard. Our water tank is now able to achieve heating loss A+. Additionally, ISO9001, ISO14001, ISO45001 and all other materials are certified ROHS.

SST have stainless steel material laboratory for raw material the laboratory include: component analysis of raw materials and spectrograph test. It can confirm that our raw materials are in line with ROHS and standards. boiler and hot water cylinder, to evaluate different stainless steel materials' corrosion resistance; Metallographic test, to determine the changes in the chemical composition of raw materials and materials following welding. Tensile test to test the strength, toughness, and fatigue. Also we have stress test and fatigue test for each tank, to ensure all products are qualified.