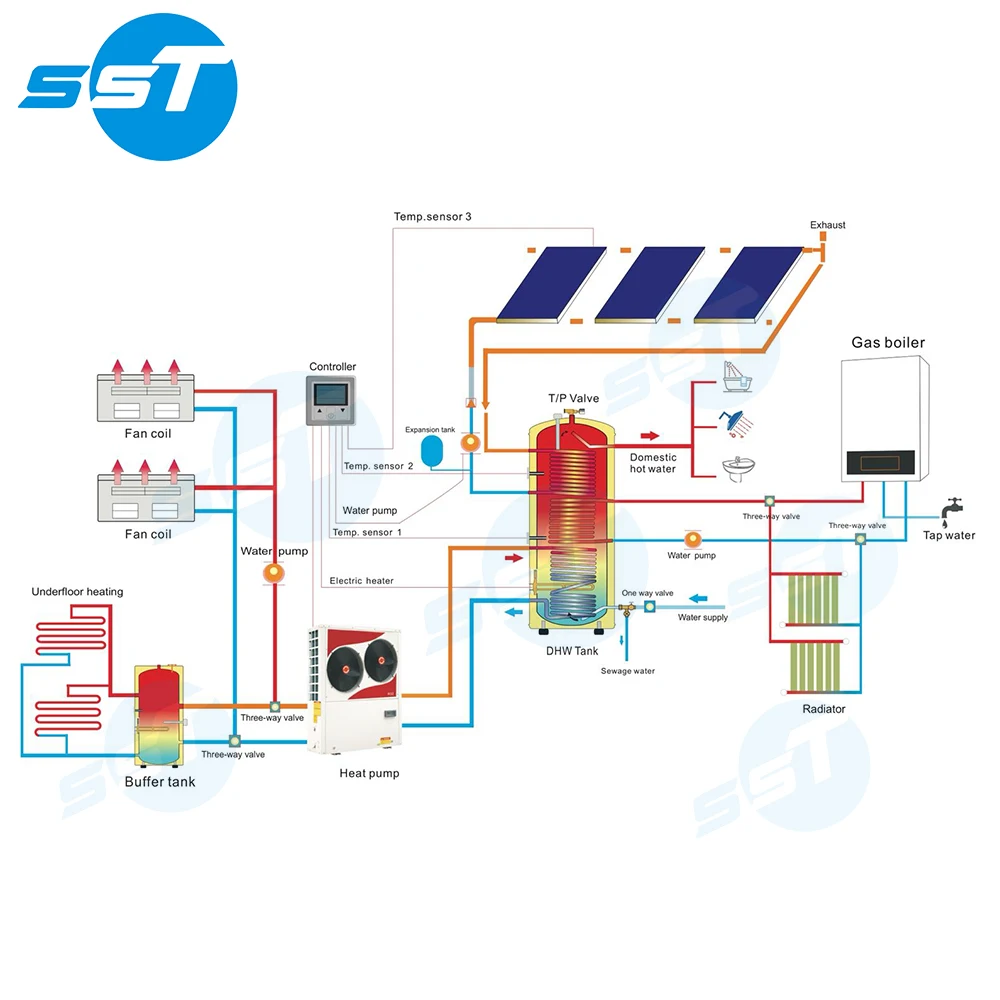

We refer to HVAC (heating, ventilating and air conditioning) system as heating and cooling systems where heat transfer coils are the significant parts. Air conditioners, found in homes, schools and workplaces are based upon these systems. Heat transfer coils work like a heat pump moving or taking away the hot air from one place and transferring (taking it to outside of building) SST water pump hot water heater move air or a liquid through them. Air or liquid passes over the coils and heat is transferred from the coils to this air or liquid. In turn, this cools down or warms up spaces depending on the function. Heat transfer coils are present in many of the appliances we use on a daily basis, like air conditioners and refrigerators even some car uses heat conductive techniques similar to that!

Functions of Heat Transfer Coils in an HVAC System The coils extract heat from buildings and expel it outside during hot weather, such as in summer. SST heat pump water heater system helps to make the inside of the building not quite as hot and sunny. During wintertime, when the weather is cold outside, these coils deliver heat from outdoor air into buildings to warm up. HVAC systems would not be very effective and Habitable buildings without these vital coils. You might feel too warm in the summer and cold in the winter.

Heat transfer coils have come a long way over the years, with continuous innovation around their manufacturing. These coils have since advanced and became increasingly more efficient. They work that way now: Copper and aluminum things we know will conduct heat really well. These materials aid the coils function at a faster and more effective rate than prior material. Perhaps the most substantial implementing improvement, however is the use of finned coils. The finned coils, which have the fins installed on them to promote increased surface areas. This enables them to transfer heat more efficiently. Some newer coils are more precise in how they can be made, making SST indirect water heaters effective. Remove At ultra-low frequencies glial to bandwidth, which improves performance. These advances all help keep an HVAC system operating smoothly and efficiently.

Finally, just like any other part of a heating and cooling system proper care is needed to make this heat transfer coil functional. This is why electric heat pump water heater is crucial to clean your eva coils regularly, as dirt and debris can accumulate on the evaporator coil preventing water from sliding off-effectively increasing superheat. Clean the coils gently and do not damage them. Likewise, have your coils inspected for damage or any signs of wear and tear. Failure to do so will result in the development of secondary issues, and if any damage is discovered it is crucial that coils are repaired (or replaced) promptly. Properly maintaining the coils also helps maintain efficient operation of HVAC systems to create a more comfortable indoor environment.

Heat Transfer Coils, as for any heat exchanger type of unit the ease to get a right selection bt fitting model in performance or just fails. There are many types of coils for the devices. These include, for example, coils designed specifically to work in air conditioning units or refrigeration systems. You also need to select a coil that is the correct size and configuration for your requirements, as well as choosing one which suits the purpose you have in mind. The proper heat transfer coil not only allows HVAC systems to perform better, but ensures that a space is comfortable for all inhabiting best heat pump water heater.

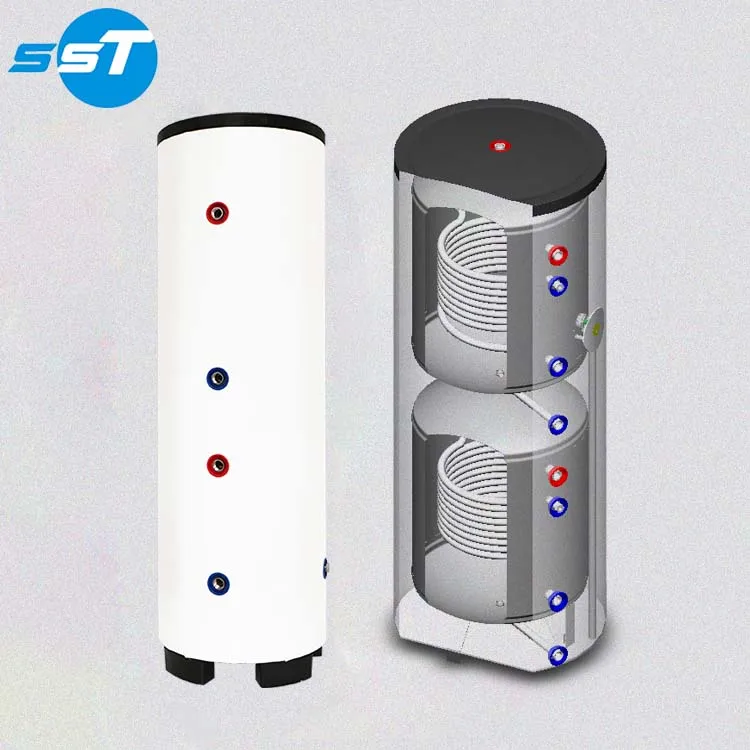

SST have stainless steel material laboratory for raw material the laboratory include: component analysis of raw materials and spectrograph test. It can confirm that our raw materials are in line with ROHS and standards. Heat transfer coils, to evaluate different stainless steel materials' corrosion resistance; Metallographic test, to determine the changes in the chemical composition of raw materials and materials following welding. Tensile test to test the strength, toughness, and fatigue. Also we have stress test and fatigue test for each tank, to ensure all products are qualified.

Concerning certification, SST had CE, Heat transfer coils, ERP, and PED to serve the Europe market. Watermark is for the Australian market, UL is for North America, KTW and WRAS are for UK drinking standard. Our water tank is now able to achieve heating loss A+. Additionally, ISO9001, ISO14001, ISO45001 and all other materials are certified ROHS.

SST Heat transfer coils include heat pump water tank buffer tank made of gas, gas boiler electric water tank pressure solar water tank hot water tank storage water tank the heat recovery tank solar system accessories and related stainless steel customized products. SST offers OEM and ODM service 20 Technology, RD engineer, six automated production line to ensure welding quality and efficiency.

SST Heating Energy Co., Ltd was formed in the year 2006. It is the world's largest manufacturer of Heat transfer coils stainless water tanks, which use the latest technology. Obtains more than 50 inventions and utility patents. Over 18 years SST has been exporting water tanks and is No. 1 in the exports of water tanks. Factory area exceeds 30000m2, and monthly production of 10, 000 pcs. Heating loss is as high as A+.