Heating underfloor This is the same as home heating. This is where under floor heating systems come into play that uses a special pipe laid down inside the floor, to make certain heat can be equally spreaded around every room of your home. Furnishing a warm place to be in winter. Nevertheless, on occasion there are issues with underfloor heating. These issues can result in some parts of your home becoming chilly, or they could amount to energy costs that surprise you. To assist in alleviating these problems, a buffer tank can come to the rescue and will also enhance your underfloor heating system performance.

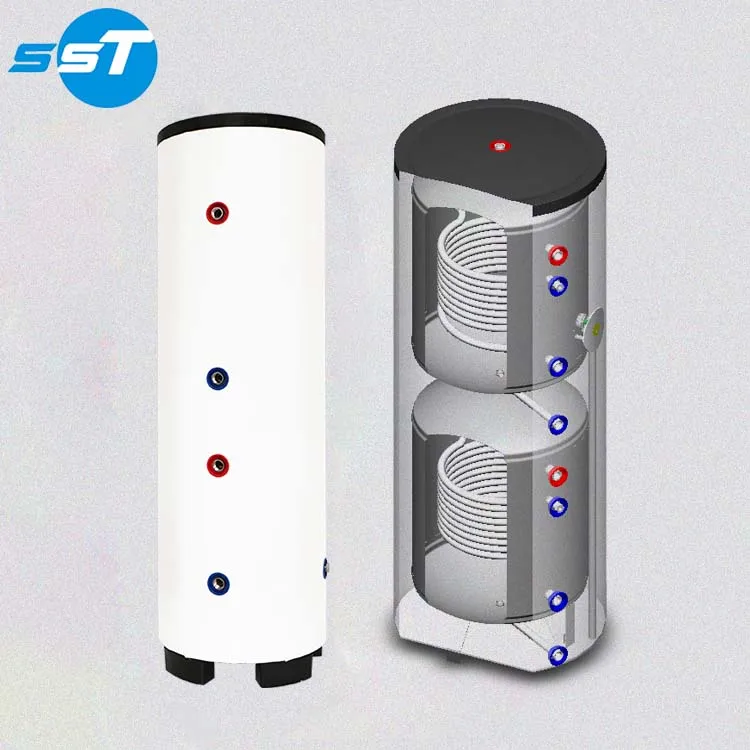

The buffer tank is an essential element of the underfloor heating system. A unique tank designed for holding hot water. A Manifold tankThe manifold tank is linked to the wet UC underfloor heating system, and it has very important functionality. The pipes below the floor are served with water through the buffer tank that stored warm. This therefore prevents the heating system from overworking, and instead dictates it to work in a consistent manner. The buffer tank stores hot water for later use to ensure that it is available when required.

Buffer Tank Required (+ Why this is So Important) For one, it helps to protect the boiler (the thing that actually heats up water). Those who require fast and regular working for boiler are the ones that might make it wear out faster. This is bad because boilers are expensive to replace. The boiler has an easier life because it does not need to work as hard since you have a buffer tank. It also to ensures that the tubes remain at a constant temperature, thanks partially to the buffer tank. Buffer Tank – It ensures that the hot water stored in it retains its temperature. This effectively means that a heating system doesn't need to generate heat while the house is warm, hence saving you some energy and potentially lowering your electricity bills.

Lack of Speed- A typical issue with underfloor heating is that it can take ages to heat a room. This is because the pipes are distributed in a wide area and it will take some time for all of them to get heated. A buffer tank stores hot water so that it can be used whenever needed. This means underfloor heating system can heat the room much quicker, which could be a lot more pleasurable for your and your household.

A common challenge that people face is maintaining proper home temperature. Buffer tank, this is important because if the boiler turns on and off often enough you will get cold temperature water flowing in your pipes. This apparently leads to irregular heating, so some spots might be hot and others cold. The buffer tank keeps the temperatures constantly in check. This in turn helps keep the process steadier, keeping you from experiencing starts and stops of warmth.

In addition, a buffer tank allows you to save resources as well making it more sustainable and healthy for the environment. The buffer tank can contribute to reducing energy bills, thanks the boiler works more efficiently. If a heating system performs more efficiently, it uses less energy which is better for our planet. Finally, a buffer tank will also help to increase the life of your heating system. So with a longer lasting system, there will be less of a need for repair and/or replace which is not only good news on your wallet but great for the environment.

buffer tank underfloor heating products include water heater for heat pumps, gas boiler tank, buffer tank, electric water tank pressure solar water tank hot water tank storage tank for water, heat recovery water tank and solar system-related accessories and related stainless steel customized products. SST offers ODM and OEM solutions, 20 technology and RD engineers, and 6 automatic production lines to ensure the highest quality welding.

SST has a stainless steel lab to test raw materials. The lab includes component buffer tank underfloor heating of raw materials and spectrograph tests to ensure our raw materials are in conformity with standards and requirements for ROHS; point corrosion test for comparing the corrosion resistance of different stainless steels and metallographic tests to test changes in the chemical composition of tissues after welding the material; tensile test to measure strength, toughness and fatigue. There are also test for fatigue and pressure in every tank to make sure that the products are certified.

SST Heating Energy Co., Ltd is founded in 2006, is the most significant manufacturer and exporter of custom stainless steel water tanks and the most experienced manufacturer of DUPLEX stainless steel water tank featuring the most advanced technology in China. Obtains more than 50 inventions and utility patents for model designs. Since its inception, SST has been exporting water tanks, and is No. 1 in the exports of water tanks. The factory area is greater than 30000m2, and monthly production of buffer tank underfloor heating. Heating loss is as high as A+.

SST is certified with CE CB, ERP, and CE certifications for the European market. Watermark is designed for the Australian market, UL is for North America, KTW and WRAS are intended for UK drinking standard. Our buffer tank underfloor heating has the ability to attain a heating loss of A+. Also, ISO9001, ISO14001, ISO45001 and all other materials are certified ROHS.